Horner Solutions Integrator Options

Our Solutions are Limited Only by Your Imagination

We are a family owned business of Factory Automation Solutions, Products and Knowledge. With our comprehensive range of services, BIG SKY COLONY ELECTRIC can guarantee your needs are not just met, but exceeded. We work closely with our customers to create designs that are seamlessly integrated, effective and sustainable for many years to come. Reach out today to see how we can help.

PLC Programming Systems

——————————————–

Smokers

Creating consistent cooking results with your wood pellet smoker with temperature control and thermal regulation.

——————————————–

Make-Up Air Systems

A Make-up Air unit pulls air into your space from outdoors and conditions it to the indoor temperature, to replace air that’s pulled out by your kitchen exhaust equipment. Without it, you get back drafting, poor temperature control, negative air pressure and air quality problems. Big Sky can provide a PLC with advanced control logic and system communication.

——————————————–

Agriculture Industry

Hog Barns

- We build and install technology for grain handling. Custom touch screen controls, bin level monitoring systems. A system like this gives complete control over your grain handling systems. The controlling and monitoring of the grain storage area is fully automated using PLC Separators, Ventilation, and Water Treatment.

Dairy Barns

- A scheduled maintenance program can help prevent major system breakdowns and costly down time. Make an animal feeding system for a variety of uses – cattle raising, farms, horse stables and many more. The feeding process will be automatized using an industrial controller which controls the feeders and will keep track of the food for periods, quantities and food types.

- Machine automation solutions for separation technology have been designed to ensure high usability and ease of maintenance. The controls offer many features for operation under various conditions regarding safety, quality and regulations for calf feeding solutions, separators, scrapers and ventilation.

Chicken Barns

- Poultry automation ensures optimum farming condition. As a poultry farmer, it is of crucial importance to achieve the proper housing conditions for your animals. It allows them to grow better and perform optimally. The key to attaining the best possible control of your production process is automating and monitoring your barn processes. With our poultry automation systems you have 24/7 insight into the current situation in all of your barns, allowing you to focus on an optimum living environment for your animals.

Greenhouse

- The monitoring of temperature and humidity in your greenhouse, as well as overall soil temperature and humidity, is very important for the growth of plants. By using greenhouse automation you can increase the productivity. This system is based on monitoring and controlling the parameters that play important roles in greenhouses. We will give you accurate results about what activities should be performed in the greenhouse, taking into consideration the different environmental conditions in which this system is used.

——————————————–

Irrigation

An Automated Irrigation System using PLC Programming. Farmers will be able to monitor and control their irrigation system from one place. Sensors and methods are available to determine when plants may need water. It also improves the speed of production.

——————————————–

Engineering & Tech Services for a Variety of Industries

We provide full services in planning, designing, schematics, programming, panel assembly and implementation. We can also assist you by working from your existing plans, schematics and/or drawings by upgrading, re-programming or redesigning an existing control system. Serving the Car Wash, Fire Station, Parking Garage, Auto Dealership, Service Station and Agriculture Facility Industries.

We provide mechanical and electrical engineering services and will customize your system for your needs.

——————————————–

Control Panels

C.W. Automation Inc., is UL Certified in multiple UL listings including UL508 and we’re capable of taking on any size project. From a custom 1-off panel to a run of 100 panels, we will support you in designing and selecting the right components for your specific needs. We have expert understanding of control applications, panel production and Customer Service requirements in the most dynamic & demanding industries to make your project’s panel design accurate and the installation simple.

- We can also do just panel assembly with customer supply Bills of Materials and Drawings if so required.

- All of our industrial control panels can be engineered, constructed and UL listed.

——————————————–

Door Industry

SAFETY OPTIONS:

- Safety Eyes, Safety Edge (2 wire, 4 wire, monitored or fail safe), Light Curtains, Load Sensing, Stop Buttons, Motion Sensors, Presence Sensors, Loop Detectors, Radio Controls

OTHER OPTIONS:

- Keypads, Battery Backup, Internet Connectivity, Master Control Stations, Interconnecting Multiple Doors, Emailing, Texting

- Extended Door Life

- Energy Savings

- Speed

- Voltage Options

- Remote Connectivity

- Technical Support

——————————————–

Agriculture Industry

We have many years’ experience in designing, building and electrically servicing control systems for many areas of agriculture including:

- Manure handling and processing for the Dairy Industry

- Drying

- Screw Presses

- Pumping

- Digesters

- Barn fan controllers

- Custom and off the shelve controllers for running fans in barns and free stall barns

- Tunnel Type fan controllers

- Smart controllers to automatically sense the inside and outside temperature and adjust the fan speeds automatically without the need for human interface.

- Grain Handling

- Custom grain dryer control panels to operate many different style driers, come to us with your drying process and we will develop a cost-effective solution.

- Grain handling, conveying and auguring.

- Grain Blowers, we have a standard design grain blower for blowing grain through tubes from point A to point B.

——————————————–

Dust Collectors

C.W. Automation Inc., has experience in building and electrically servicing control systems for HVAC Systems for O.E.M’s per their specifications.

- We can build from engineered plans that you bring to us or we can design and develop a system for your HVAC, based on the requirements and process you need.

——————————————–

Concrete

Designing, building and electrically servicing control systems for concrete batching systems:

- Control Panel design, build and commissioning.

- Handing of material and batched up to load amount for concrete truck.

- Load cells

- PLC Control with touch screen and datalogging for each batch and the capability of printing out a load receipt for record keeping and invoicing.

- Spare parts are also a part of our business.

- Technical Support

——————————————–

Pump Control

Designing, building and electrically servicing control systems for pumping of liquid and dry materials:

- Level Control for Sump Pumps with smart PLC and Liquid Level sensing to automatically either fill or drain a vessel to a desired level. The level detection can be done with either Analog or Discrete signaling.

- Simple Control to Touch Screen/PLC Control depending on the application requirements.

- Lead/Lag Pump Designs with Hand / Off / Auto Controls

- Run Time Hour Meters for predictive maintenance of pumps and motors.

- Industrial Pressure Washers

- Run Time Hour Meters for predictive maintenance of pumps and motors.

- Multiple motors if needed to maintain proper pressure in systems depending on the usage requirements.

- Lift Station Control Design and Panel Assembly.

——————————————–

Material Handling Systems

Designing, building and electrically servicing control systems that handle and convey just about any type of material:

- Depending on your company’s needs, just come to us with your process and your ideas with what you want to accomplish, and we will work with you to come up with a design to fit your needs. We do all of our own in-house engineering and can customize to your needs.

Primary Controls Engineering

Hallfield Controls, Inc. is a small, locally owned engineering company with electrical design, programming, and UL508A panel shop capabilities. They have been in business since 2009 and have commissioned many projects across many markets using a Horner PLC/HMl.

They work very closely with local distribution as their primary controls engineering partner. They have designed, built, and programmed many systems over the years using Horner products. They have designed many typical machine-control systems as well as many non-typical systems using the Horner product line. Hallfield has pretty much used every PLC/HMl as well as remote l/O in a variety of control panels in many different markets. Their senior programmer has been working with Horner PLCs since the GE days.

——————————————–

On-Demand Control Systems Engineering

The Hallfield Controls, Inc. manufacturing shop is centrally located in Big Lake, MN. They have done extensive work in the Twin Cities and St. Cloud Metro areas, as well as throughout the United States and in other countries.

Few other businesses deliver the wide variety of services they provide. They don’t have many competitors that are able to perform at the same level with the same expertise.

——————————————–

Customized Projects for Diverse Markets

-

- Industrial Automation

- Fluid Control Systems

- Medical Manufacturing & Equipment

- Test & Measurement

- Aerospace & Defense

Exceptional Engineering Services

Our core services center on controls, but we have a talented team that includes experts in a broad range of high-tech services. We’ll customize our solutions to meet your needs.

Areas of Expertise

Automation areas:

- Mixer equipment

- Conveyor control

- Automated assembly

- Material processing

- Injection molding automation

- Plastic grinding equipment

- Automated sawing equipment

- Automated nailing equipment

Medical Manufacturing projects:

- Filter testing

- Dispensing equipment

- Pill counters

- Mixing equipment

- Leak testing

- Tank blanketing

- Catheter testing

Measurement Equipment experience:

- Relief valve testing

- Regulator testing

- Solenoid valve testing

- Injector testing

- Pressure gauge testing

- Cycle testing

- Burst testing

- Proof testing

- Hose testing

Aerospace and Military / Defense applications in the following areas:

- Tank blanketing

- Fuel delivery

- Engine testing

- Leak testing

- Gas delivery system

Industrial Monitoring Solutions

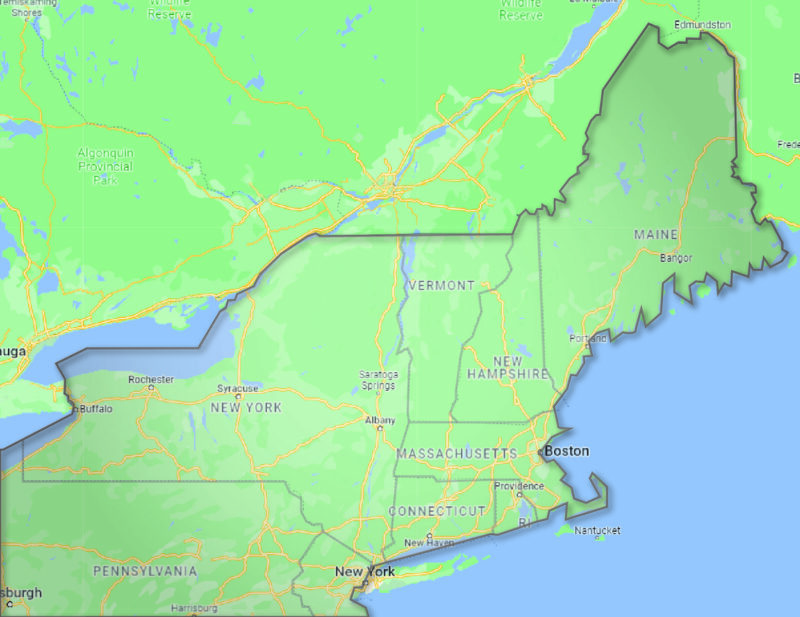

The Northeast Integration team, based out of New England, has over 100 combined years of industry experience supporting factory automation, information systems, power generation, OEM equipment design, process control and SCADA systems.

——————————————–

NEI Ether Industrial Information and Monitoring Suite – Summary and Product Description:

The NEI Ether System Monitoring Service is a secure and efficient solution for managing industrial processes, offering a range of communication protocols, advanced alarm modules, and reliable data collection to maintain constant connectivity and information flow.

At the core of the system is the NEI Ether Gateway Device, which supports multiple industrial communication protocol drivers, a versatile alarming module, and a dependable data collection module. The built-in VPN Gateway enables integrators to remotely diagnose and program various industrial control systems, such as PLCs, HMIs, and drives. The store-and-forward mechanism ensures no data loss when network connectivity is compromised, while the optional one-way network diode enhances network protection.

The NEI Ether Backend Cloud Infrastructure allows monitoring of registered gateway devices, tracking of connectivity and health, and reception of alarm and data collection updates via SMS, email, voice, and push notifications. The time-series database storage and periodic status reports provide access to up-to-date operational data. The NEI Ether Backend Overwatch, an integral part of the Backend Cloud Infrastructure, continuously monitors the cloud service health.

NEI Ether Mobile Applications for Android and iOS facilitate gateway device management, alarm condition setup, and notification recipient designation. The alarm state interface streamlines end-user communication.

Finally, the NEI Ether WebApp offers customizable data visualization and reporting, utilizing the time-series data collected by the backend. Auto-generated Excel spreadsheets for trends, tables, gauges, states, and more are delivered through your chosen notification system.

In summary, the NEI Ether System Monitoring Service provides a comprehensive solution for staying connected and informed, enabling better control over industrial processes.

——————————————–

System Architectural Description:

NEI Ether Gateway Device —

- Industrial Communication Protocol Drivers (Ethernet, RS232, RS485)

- Alarming Module

- Data Collection Module

- VPN Gateway Module

- Store and Forward Mechanism for Alarming and Data Collection Modules

- Optional One-Way Network Diode

NEI Ether Backend Cloud Infrastructure

- Monitor Registered Gateway Devices

-

- Alarm Module

- Track Connectivity and Health

- Receive Alarm Module States

- Log Events to Database

- Provide Periodic Usage Reports

- Deliver via Notification System (SMS, Email, Voice, Push Notifications)

- Gateway Connectivity and Health

- Alarm Conditions

- Data Collection Module

- Time-series Database Storage (InfluxDB)

- Periodic Status Reports (Scheduled Interval)

- Delivered via Notification System

- Alarm Module

NEI Ether Mobile Applications (Android, iOS)

- Manage/Configure Gateway Device

- Authenticate with NEI Ether Backend Infra

- Alarm Module Setup (Conditions)

- Notification Recipients (Name, Phone Number, Email, App)

- Recipient Schedules and Hierarchy

- Alarm State Interface

- End User Communication (Notes, Acknowledgments, History)

NEI Ether Backend Overwatch

- Monitor NEI Ether Backend Cloud Service Health

NEI Ether WebApp Data Visualization and Reporting

- Dashboards

- Utilizing Data Collection Database

- Customer Configurable

- Trends, Tables, Gauges, States etc…

- Reporting

- Auto Generate Excel Spreadsheets

- Deliver via Notification System (Email, Shared Cloud Storage)

OpenApps Full Service System Integration

William (Bill) Rinear launched OpenApps in 2000 with a goal to help clients with whatever integration challenges were presented. “Open” to anything – we adopted a policy of complete transparency and project ownership for clients. Even today, the expectation is that the work and standard code (applications) produced by OpenApps remains open for client modification.

——————————————–

We’re a full-service systems integration company. Our specialty is managing projects from product concept to development and completion. Industries and capabilities include, but are not limited to: Food processing, Manufacturing, and R&D Testing.

OEM & PANEL BUILDING

Our UL508 panel shop works with you to meet your needs. We will take you from concept and design to a finished, simulated, and 100% tested product. Whether you need one panel now or duplicates throughout the year, we are here to support you throughout your project.

RETROFITTING/AUTOMATION UPGRADES

When outdated technology stalls your manufacturing process, you need someone fast and reliable to get you back up and running so the financial loss is minimized. At OpenApps, we understand your need and will work tirelessly to bring your legacy equipment up to current standards in technology, helping you save money in your manufacturing.

M2M & REMOTE MONITORING

Machine-to-Machine Remote Monitoring that allows for more productive communication between the field device and your company’s service, sales, and reorder points. At OpenApps, we can set up monitoring systems to alert a technician when tank levels are low; we can control the lighting at parks and ball fields; when you need machines to communicate, we’re on it.

——————————————–

Liquid Dosing System

Liquid Dosing Systems eliminate the guess work in the dosing of fuels and other liquids. It features an easy to operate user interface that relies on color touchscreen controls and fully automatic operation with alarming and quick shutdown. The flexible design of our liquid dosing systems can accommodate a variety of liquids, flow rates, and installation requirements and is available as stand-alone, rack-mount, table-top, in-line, and portable units.

- Automatic Modes Include:

- Alarming and Quick Shut Down

- Totalizing Mode: For pumping a desired volume

- Fueling Mode: For pumping a volumetric ratio in real time

- Manual Mode for:

- Testing

- Troubleshooting

- Calibration

- Fully capable controller allows custom programming for specific requirements

- Built-in security features

Product Link: https://psctexas.com/chemical-dosing-system

Product Images: https://drive.google.com/drive/folders/1IQk-TWA254FA6EcKYPKn88RcREez3G_c?usp=share_link

——————————————–

OxyPro Oxygen Deficiency Monitor

Built for longevity and accuracy, this oxygen detector uses non-consumable paramagnetic technology to detect oxygen, offering an alternative to oxygen detectors that use fuel cells, which deplete over time. Using a paramagnetic oxygen detector will virtually eliminate routine maintenance and calibrations in exchange for increased safety, reliability, and lower cost of ownership.

- excellent measurement stability and non-consumable sensor eliminates daily calibrations

- optional ambient or sample pressure compensation

- remote access and live monitoring

- lifetime technical support and lower lifetime cost of ownership

Product Link: https://psctexas.com/oxypro

Landing Page: https://psctexas.com/oxygen-detector

Product Images: https://drive.google.com/drive/folders/1I8GsJP6SoD0t2Q1R8U407N5dORT-YFvR?usp=share_link.

——————————————–

Gas Bottle Pressure Monitoring System

Our Gas Bottle Monitor is designed to constantly monitor the pressure of industrial gas bottles and pressurized analyzer gas tanks. This system is ideal for preventing critical analyzer shutdown or emergency gas deliveries and will notify operators when supply is running low, which eliminates the need for manual operator rounds.

Never Run Out of Gas Again

- transmit pressure to DCS via Modbus TCP

- visually indicates pressure / volume

- alarm notifications when bottles are running low via text, email, or LED light

- cost effective solution

- eliminate manual operator rounds and emergency gas deliveries

- QR code integration to indicate serial/lot number, concentration, installation/expiration date, etc.

Product Link: https://psctexas.com/gas-bottle-monitor

Product Images: https://drive.google.com/drive/folders/1HeoAoZM54S9S-2Olw5yrsbXZSQGsPK6A?usp=share_link

——————————————–

Gas Mixing System for Homogeneous Gas Mixtures

For many processes, very accurate compositions of gas are required, which means simply adding two or more gas streams together isn’t sufficient. Our gas mixing systems enable operators to create accurate and precise gas compositions of two or more gases. Our gas mixers allow a repeatable and reliable process that helps eliminate discrepancies and ensures that operators have access to the exact gas compositions their processes require at any time. Mixing your own gas increases process efficiency and helps reduce the cost of having to purchase premixed gases.

- create homogeneous gas mixtures from percentages down to ppm-ranges

- high accuracy and repeatability with a fast response

- flow ranges from 300 mln/min up to 10,000 mln/min

- pressure rating up to 100 bar

Product Link: https://psctexas.com/gas-mixing-system/

Product Images: https://i0.wp.com/psctexas.com/wp-content/uploads/2022/09/Gas-Mixing-Chamber_bronkhorst-flow-instrumentation-meters-flow-controllers-shop-online-process-solutions.png?fit=500%2C500&ssl=1

——————————————–

Controlled Vapor Generation

The PSC Controlled Evaporation System is a vapor generation system designed to generate low flow vapor streams. This system is an alternative to traditional bubbler systems and provides a highly precise, repeatable, and controllable vapor generation process. Our fully integrated packages can be custom designed to fit your exact project requirements. These vapor generation systems arrive assembled and ready for use and are backed by our technical support team. They are available as rack-mounted or table-top units for the following applications:

- chemical vapor deposition (CVD) and metalorganic CVD

- advanced alternative to traditional bubbler systems with improved repeatability

- electric and dielectric (insulating) layer deposition on semiconductors

- humidification of fuel cells for renewable energy

- generate reference gas for analyzers and gas chromatographs

- medical applications such as dosing anesthetics, sterilization, mRNA vaccine production, etc.

- crystal breeding installations

- dosage of additives for manufacturing, e.g. perfume, vitamins, etc.

- food and beverage production for fermentation, aseptic packaging, flavorings and additives, etc.

Product Link: https://psctexas.com/vapor-generation

Product Images: https://drive.google.com/drive/folders/1FybctXCQizlCmiuDQI3g9np-AT88tCK8?usp=share_link

Mass Flow Controller

The PSC6194 Flow Controller is a custom engineered readout and control system for use with the Bronkhorst Flow Meters and Controllers. It features a color touch screen display, which enables the user to easily view or change functions and delivers a big picture into an overall small package. With its 4.3″ wide aspect screen and hidden soft key technology, you can use the entire screen to display and interact with up to 4 flow meters and controllers. Its preprogrammed logic includes the indication and operation of:

- Measured Value

- Setpoint

- Instrument Range

- Trending Values Totalizer (limit, value, totalizer mode, new setpoint)

Product Link: https://psctexas.com/flow-controller

Product Images: https://drive.google.com/drive/folders/1JjwsqKqBDBLt9iGyRlmAFwVrwwBK0Aco?usp=share_link